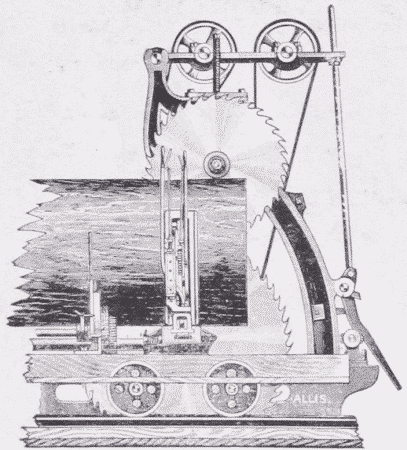

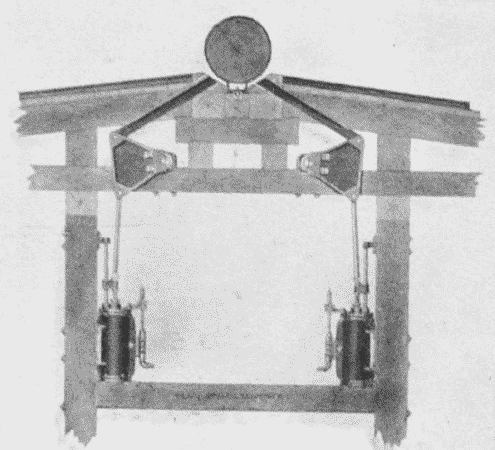

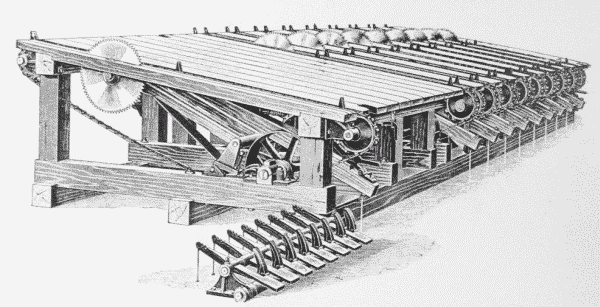

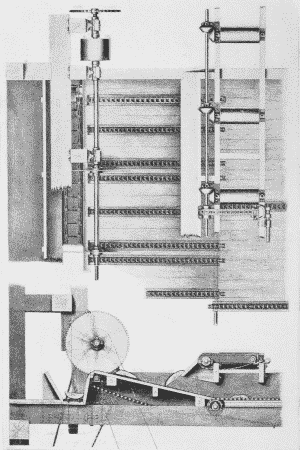

The principal saws in a mill are of three kinds, the circular, Fig. 32, the gang, Fig. 33, and the band, Fig. 34. The circular-saw, tho very rapid, is the most wasteful because of the wide kerf, and of course the larger the saw the thicker it is and the wider the kerf. The waste in sawdust is about one-fifth of the log. In order to lessen this amount two smaller saws, one hung directly above the other, have been used. One saws the lower half of the log and the other the upper half. In this way, it is possible to cut very large logs with the circular-saw and with less waste. The circular-saw is not a perfectly flat disc, but when at rest is slightly convex on one side and concave on the other. This fullness can be pushed back and forth as can the bottom of an oil-can. When moving at a high rate of speed, however, the saw flattens itself by centrifugal force. This enables it to cut straight with great accuracy.

Fig. 32. Double Circular-Saw and Carriage.

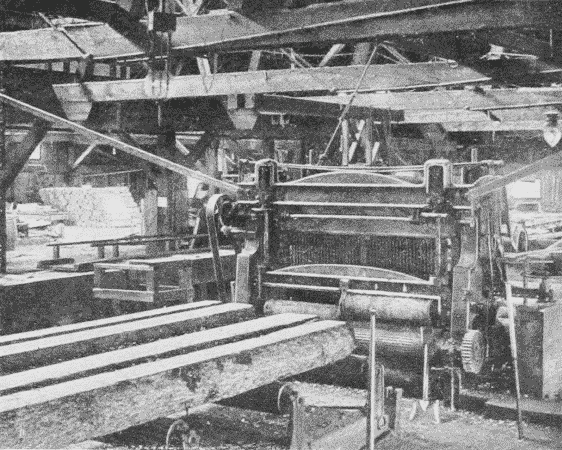

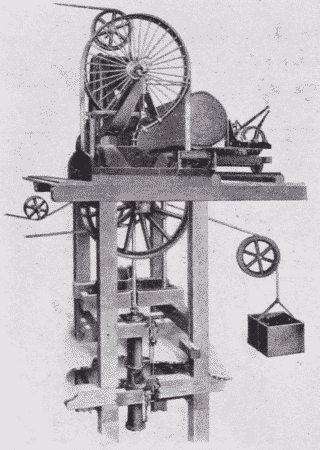

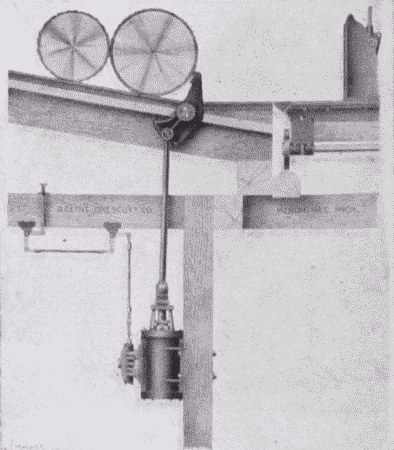

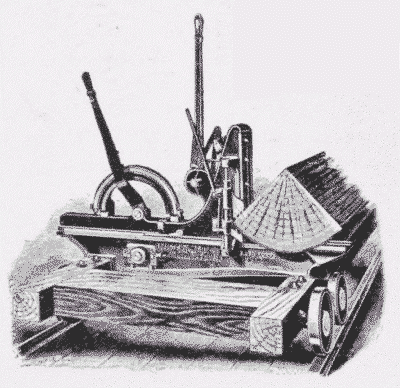

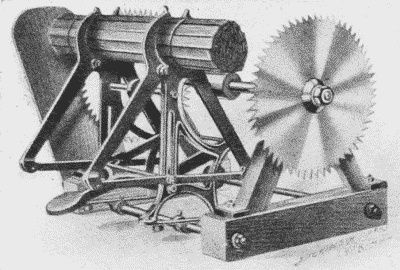

A gang-saw is simply a series of straight saw-blades set in a vertical frame. This has a reciprocating motion, enabling it to cut a log into a number of boards at one time. It has this drawback, that it must cut the size of lumber for which it is set; that is, the sawyer has no choice in cutting the thickness, but it is very economical, wasting only one-eighth of the log in sawdust. A special form is the flooring gang. It consists of a number of saws placed one inch apart. Thick planks are run thru it to saw up flooring.

Fig. 33. Gang-Saw.

Fig. 34. Band-Saw.

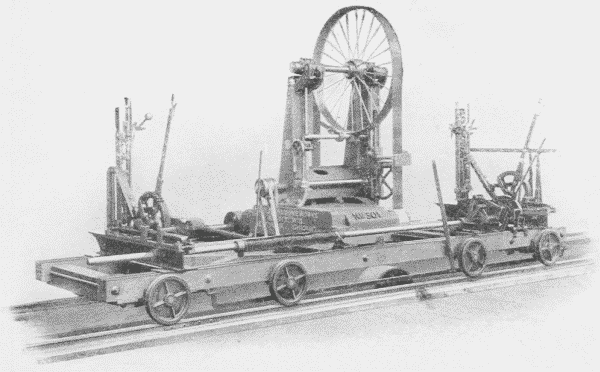

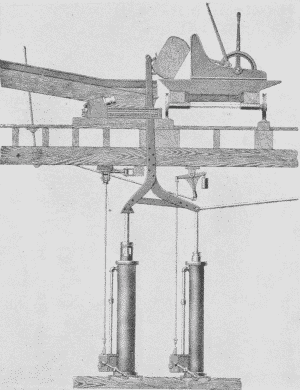

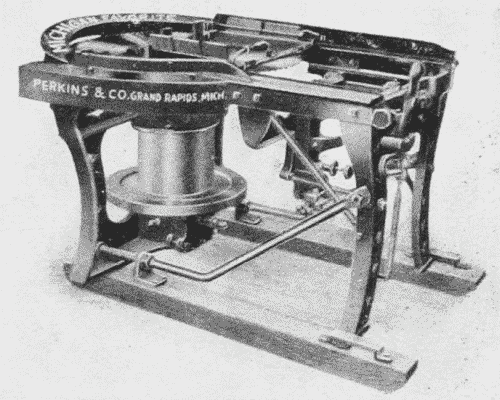

The band-saw is fast displacing the other two, wherever it can be used. It cuts with great rapidity and the kerf is narrow. When first used it could not be depended upon to cut straight, but by utilizing the same principle that is used in the circular-saw, of putting the cutting edge under great tension by making it slightly shorter than the middle of the saw, it now cuts with great accuracy. Band-saws are now made up to 12 inches wide, 50 feet long, and run at the rate of 10,000 feet a minute. They are even made with the cutting teeth on both edges, so that the log can be sawed both going and coming. This idea was unsuccessful until the invention of the telescopic band-mill, Fig. 35. In this the entire mechanism carrying the wheels on which the band-saw revolves can be moved up and down, so as to bring the point where the saw leaves the upper wheel as close to the top of the different sized logs as possible.

Fig. 35. Double-Carrying Telescopic Band-Mill.

Fig. 36. Jack-Ladder, with Endless Chain. Mill in raised position for large log.

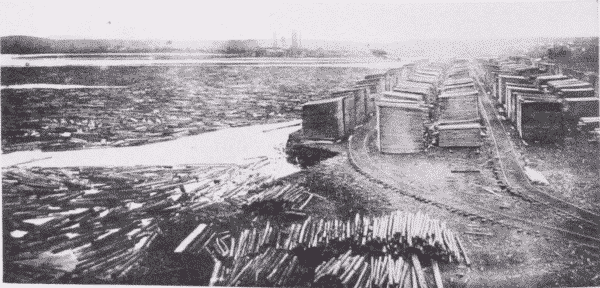

The usual modern mill is a two story building, Fig. 37, built at a convenient locality both for receiving the logs and for shipping the lumber. Whether the logs arrive by water or by rail, they are, if possible, stored in a mill-pond until used in order to prevent checking, discoloration, decay, and worm attack. From the pond they are hauled up out of the water on to a “jack-ladder,” by means of an endless chain, provided with saddles or spurs which engage the logs and draw them up into the second story on to the log slip, Fig. 36.

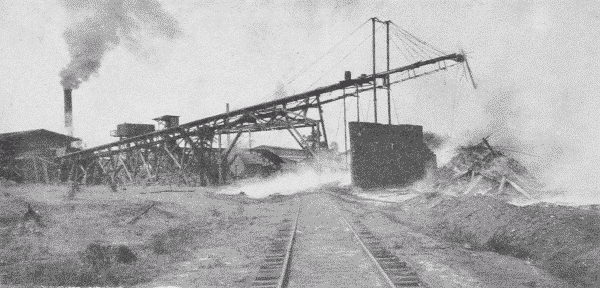

Fig. 37. Two-Story Mill at Virginia, Minnesota, Showing Jack-Ladders and Consumer.

Fig. 38. Log-Flipper.

Fig. 39. Log-Stop and Loader. By letting steam into the cylinder, the projecting arm revolves, rolling one log over onto the carriage and holding the next one till wanted.

After the logs have entered the mill, they are inspected for stones lodged in the bark, and for spikes left by the river men, and then measured. Under the log-slip is the steam “flipper” or “kicker,” Fig. 38, by means of which the scaler or his assistant, throwing a lever, causes the log to be kicked over to one side or the other, on to the log-deck, an inclined floor sloping toward the saw-carriage. Down this the log rolls until stopped by a log-stop, or log-loader, Fig. 39, a double-aimed projection, which prevents it from rolling on the carriage till wanted. This stop is also worked by steam. By letting the steam into the cylinder which controls it, one log is rolled over on the carriage and the next one held. The log on the carriage is at once “dogged,” that is, clamped tight by iron dogs, the carriage is set for the proper cut, and moves forward to the saw which cuts off the first slab. The carriage is then “gigged” or reversed. This operation offsets the carriage one-eighth of an inch so that the log returns entirely clear of the saw. In the same way two or three 1″ boards are taken off, the dogs are then knocked out, and the log canted over half a revolution. This is done by means of a steam flipper,” Fig. 40, a long, perpendicular toothed bar which comes up thru the floor, engages the log, and turns it over till the sawn side comes up against the knees of the carriage. The log is dogged again and a second slab and several boards are taken off. The log or “stock” as it is now called, is 10″, 12″, 14″, or 16″ thick; the flipper then gives it a quarter-turn, leaving it lying on a sawn side. It is dogged again, and all sawn up except enough to make a few boards. This last piece is given a half-turn, bringing the sawn side against the knees, and it is sawn up. Each board as it is sawn off is thrown by the board-flipper or cant-flipper,2 Fig. 41, on to the “live rollers,” which take it to the next process. Another log comes on the carriage and the process is repeated.

Footnote 2: A “cant” is a squared or partly squared log.

Fig. 40. The Steam Flipper.

The toothed bar turns the log over into the desired position.

Fig. 41. Steam Cant-Flipper. This machine is used to move cants, timber, or lumber from live rollers to gangs, band resaw mills, or elsewhere. The timber is discharged upon skid rollers, as shown, or upon transfer chains. |

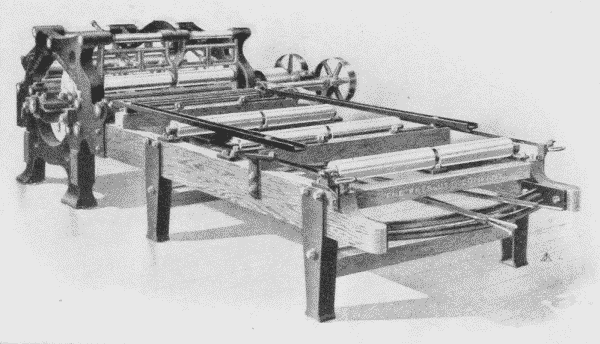

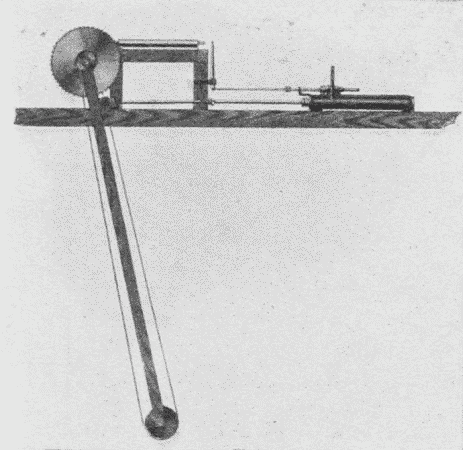

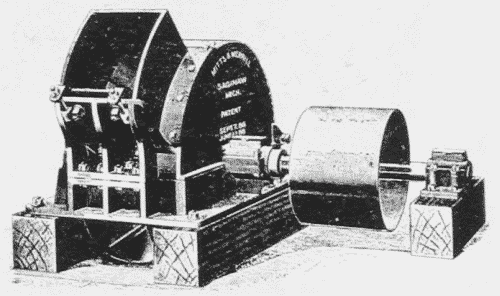

The saw-carriage, Fig. 42, is propelled forward and back by a piston running in a long cylinder, into either end of which steam can be turned by the operator.

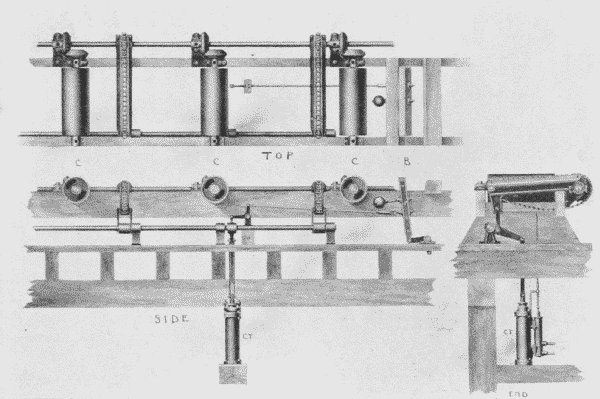

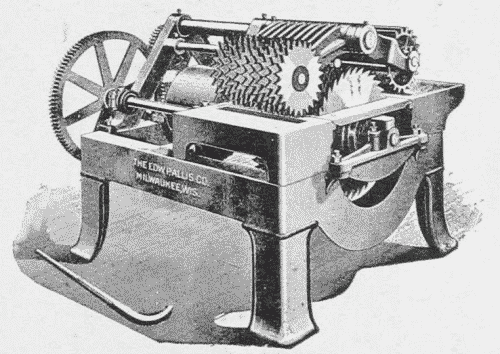

As the sawn boards fall off the log, they land on “live,” that is, revolving rollers, which carry them along at the rate of 200 to 250 feet a minute. Stops are provided farther along to stop the boards wherever wanted, as at the edger, Fig. 43, or the slasher. From the live rollers the boards are transferred automatically, Fig. 44, by chains running at right angles to the rollers and brought within reach of the edger man. About one-third of the boards of a log have rough edges, and are called “waney.” These must go thru the edger to make their edges parallel. The edger man works with great speed. He sees at once what can be made out of a board, places it in position and runs it thru. From the edger the boards are carried to the trimmer, which cuts the length. The lumberman’s rule is to “cut so that you can cut again.” The so-called 16′ logs are really 16′ 6″. The trimmer, Fig. 45, now trims these boards to 16′ 1″, so that if desired they can still be cut again. The trimmer may be set to cut at any desired length according to the specifications.

Fig. 42. Log-Carriage, holding quartered log in position to saw.

Fig. 43. Double Gang Edger. This machine trims off the rough edges of the “waney” boards by means of the four saws in the main frame of the machine.

Fig. 44. Automatic Steam Transfer for Timber, Lumber and Slabs. The boards are carried along by the cylinders, CCC, until they hit the bumper, B. This movement admits steam to the cylinder, CY, which raises the revolving chains or skids, which transfers the stock sidewise to other live rollers as required.

Fig. 45. Automatic Gang Lumber-Trimmer. It may be set to cut automatically to any desired length.

Fig. 46. Lumber Sorting Shed. Virginia, Minnesota.

Fig. 47. Wood is carefully and regularly piled in the seasoning-yard.

The boards are now graded as to quality into No. 1, No. 2, etc., Fig. 46, and run out of the mill, to be stacked up in piles, Fig. 47. Big timbers go directly from the saw on the rolls to the back end of the mill, where the first end is trimmed by a butting-saw or cut-off-saw which swings, Fig. 48. The timber is then shoved along on dead rolls and the last end trimmed by the butting-saw to a definite length as specified, and shoved out.

One of the most remarkable features of the modern mill is its speed. From the time the log appears till the last piece of it goes racing out of the mill, hardly more than a minute may have elapsed.

Fig. 48. Cut-off-Saw. This saw trims the ends of timbers.

A large part of the problem of sawmilling is the disposal of the waste. The first of these is the sawdust. In all first class mills, this together with shavings (if a planing-mill is combined) is burned for fuel. It is sucked up from the machines and carried in large tubes to the boiler-room and there is mechanically supplied to the fires. The slabs, once considered as waste, contain much material that is now utilized. From the live rolls, on which all the material falls from the main band-saw, the slabs are carried off by transfer chains, and by another set of five rollers to the “slasher,” Fig. 50, which consists of a line of circular-saws placed 4′ 1″ apart. This slasher cuts up the slabs into lengths suitable for lath or fence-pickets, Fig. 49. Or they can be resawn into 16″ lengths for shingles or fire-wood.

Fig. 49. Ten Saw Gang Lath Bolter. This machine cuts up material lengthwise into laths.

Fig. 50. Slab-Slasher. This machine cuts up the slabs into lengths suitable for lath or fence-pickets.

From the “slasher” the 4′ 1″ lengths are carried on by traveling platforms, chains, etc., to the lath-machines, Fig. 51, where they are sawn up, counted as sawn, bound in bundles of 100, trimmed to exactly 4′ in length and sent off to be stored. The shingle bolts are picked off the moving platforms by men or boys, and sent to the shingle-machine, Fig. 52, where they are sawn into shingles and dropped down-stairs to be packed. Shingle-bolts are also made from crooked or otherwise imperfect logs.

Of what is left, a good part goes into the grinder or “hog,” Fig. 53, which chews up all sorts of refuse into small chips suitable for fuel to supplement the sawdust if necessary. Band-saws make so little dust and such fine dust that this is often necessary.

Fig. 51. Combination Lath-Binder and Trimmer. With this machine the operator can trim the bundles of lath simply by tilting the packing frame over from him causing the bundles to pass between the saws, thereby trimming both ends at one movement.

Fig. 52. Hand Shingle-Machine. This machine is used in Sawmills in which it is desired to utilize slabs and trimmings by sawing shingles therefrom, or to saw shingles from prepared bolts.

If there is any refuse that cannot be used at all it goes to the scrap-pile, Fig. 54, or to the “consumer,” the tall stack shown in Fig. 37.

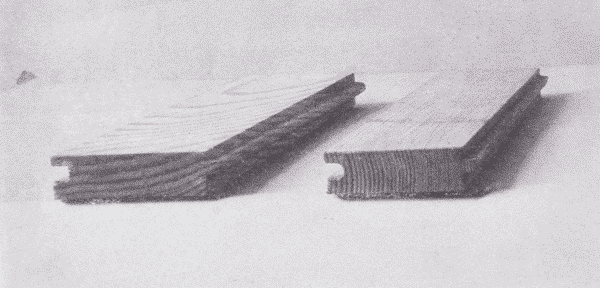

Boards ordinarily sawn from logs are “slash-sawn,” i. e., they are tangential or bastard, each cut parallel to the previous one. By this process, only the central boards would be radial or “rift” boards.

Fig. 53. Edging grinder or Hog. It cuts any kind of wood into coarse or fine chips suitable to be handled by chain conveyor or blower.

But, for a number of reasons, radial boards are better. They warp less because the annual rings cross the board more evenly. Yellow pine flooring that is rift-sawn is more valuable than slash-sawn, because the edge of the annual rings makes a more even grain, Fig. 55. Where slash-grained flooring is used, the boards should be laid so that the outside of each board will be up in order that the inner rings may not “shell out.”

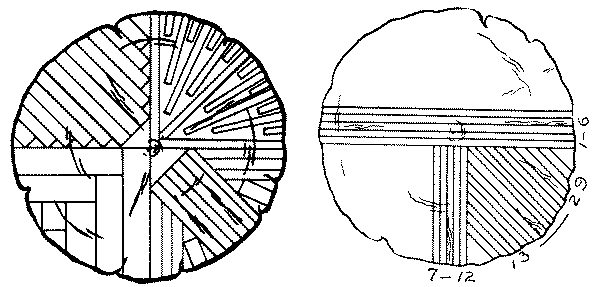

In sawing oak for valuable furniture or trim, the log is first “quartered” and then the quarters sawn up as nearly radially as is desired. There are various methods of cutting quartered logs, as illustrated in Fig. 56.

In making staves for water-tight barrels, it is essential that they be cut radially in the log, in order that the staves be as non-permeable to water as possible.

Fig. 54. Scrap-Pile. Oscilla. Georgia.

Fig. 55. Slash-Grain and Comb-Grain Flooring.

Fig. 56. Methods of Sawing Quartered Logs.

INDEX: Handwork in Wood